Intelligent Manufacturing Integrated Solution for the Steel Industry

——End-to-End Collaborative Management Platform Based on ERP + MES + AI

1. Industry Status and Challenges Analysis

1.1 Steel Industry Development Trends

- The global steel industry is undergoing its fourth industrial revolution, with digital factory construction becoming an industry consensus.

- Data from the China Iron and Steel Association shows that in 2022, key steel enterprises increased digital investments by an average of 23%, yet overall intelligent adoption remains below 35%.

- Under carbon neutrality goals, green intelligent manufacturing has become imperative. The industry urgently needs:

✓ Process optimization

✓ Precise energy management

✓ Intelligent equipment maintenance

1.2 Key Pain Points

1. Order Management

- Rising order complexity due to multi-variety, small-batch trends

- Manual scheduling inefficiencies, taking 4–6 hours for daily planning

2. Production Execution

- Siloed process data with "information funnel" effects in parameter transfer

- Critical equipment data capture rate below 60%, with vast empirical data undigitized

3. Quality Control

- Manual sampling for defect detection, averaging 12% missed rate

- Cross-system quality tracing requires 3.5 hours per case

4. Inventory Management

- Obsolete semi-finished goods inventory accounts for 25%, tying up capital

- Finished goods turnover days exceed industry benchmarks by 30%+

5. Obsolete IT Infrastructure Lock-In

- Production systems and databases run on 20+ year-old hardware, escalating maintenance costs/risks

- Siloed architecture with disconnected processes, data, and applications

- Legacy systems impede cloud, big data, AI, and IoT adoption

- Inadequate wired/wireless network coverage and communication infrastructure

6. Mismatched IT Service Cost-Efficiency

- Incumbent IT vendors charge premium rates for changes/integration, far above market levels

- Services fail to adapt to organizational workflows, hindering governance

- Knowledge gaps due to retiring/attrited IT staff make maintenance unsustainable

7. Lagging Industrial Big Data & AI

- Inability to integrate data from safety, HR, logistics, etc., for smart modeling

- Disconnected nodes prevent automated, intelligent workflow innovation

2. Solution Architecture

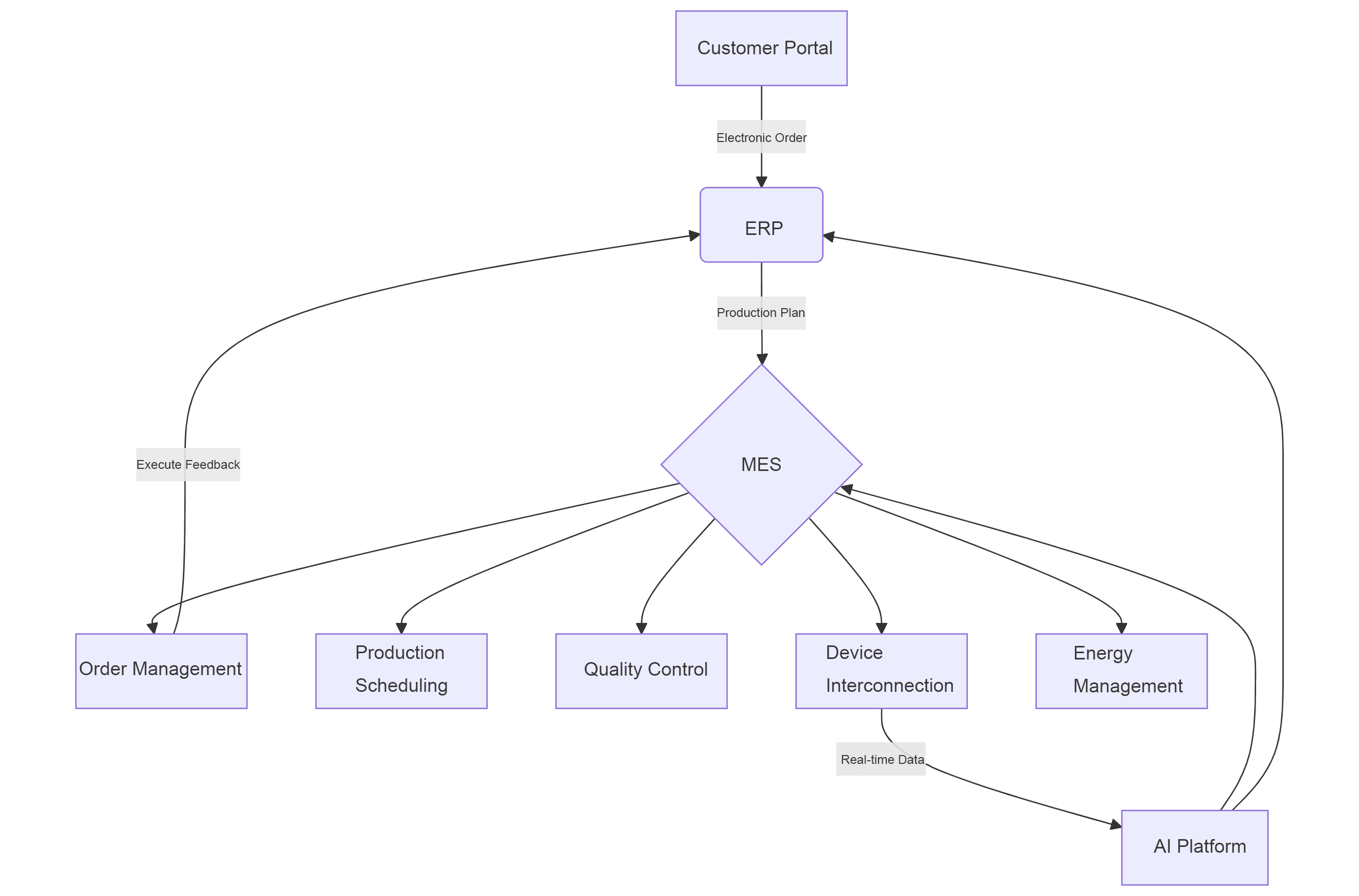

2.1 System Topology

2.2 Technical Framework

A "Cloud-Edge-Device" collaborative architecture:

- Cloud: Hosts ERP and AI training for group-wide control

- Edge: Onsite MES servers and edge computing nodes

- Device: 2,000+ equipment connected via industrial IoT gateways

3. Core Functional Modules

3.1 Smart Order Management (ERP)

- Automated Order Parsing: Supports Excel/EDI/API imports with NLP-based key field extraction

- Dynamic Capacity Assessment: Real-time MES integration for equipment status + visual load dashboards

3.2 Intelligent MES

3.2.1 Order Lifecycle Management

| Stage | Focus | Technology |

|---|---|---|

| Order Receipt | Auto-convert to work orders | Rule-based smart splitting |

| Scheduling | Equipment/process/energy constraints | Genetic algorithm optimization |

| Execution | Real-time progress tracking | Industrial APP mobile alerts |

| Completion | Auto-triggered QC | Workflow engine |

3.2.2 Digital Process Standards

- Unified process knowledge base

- Key parameter controls

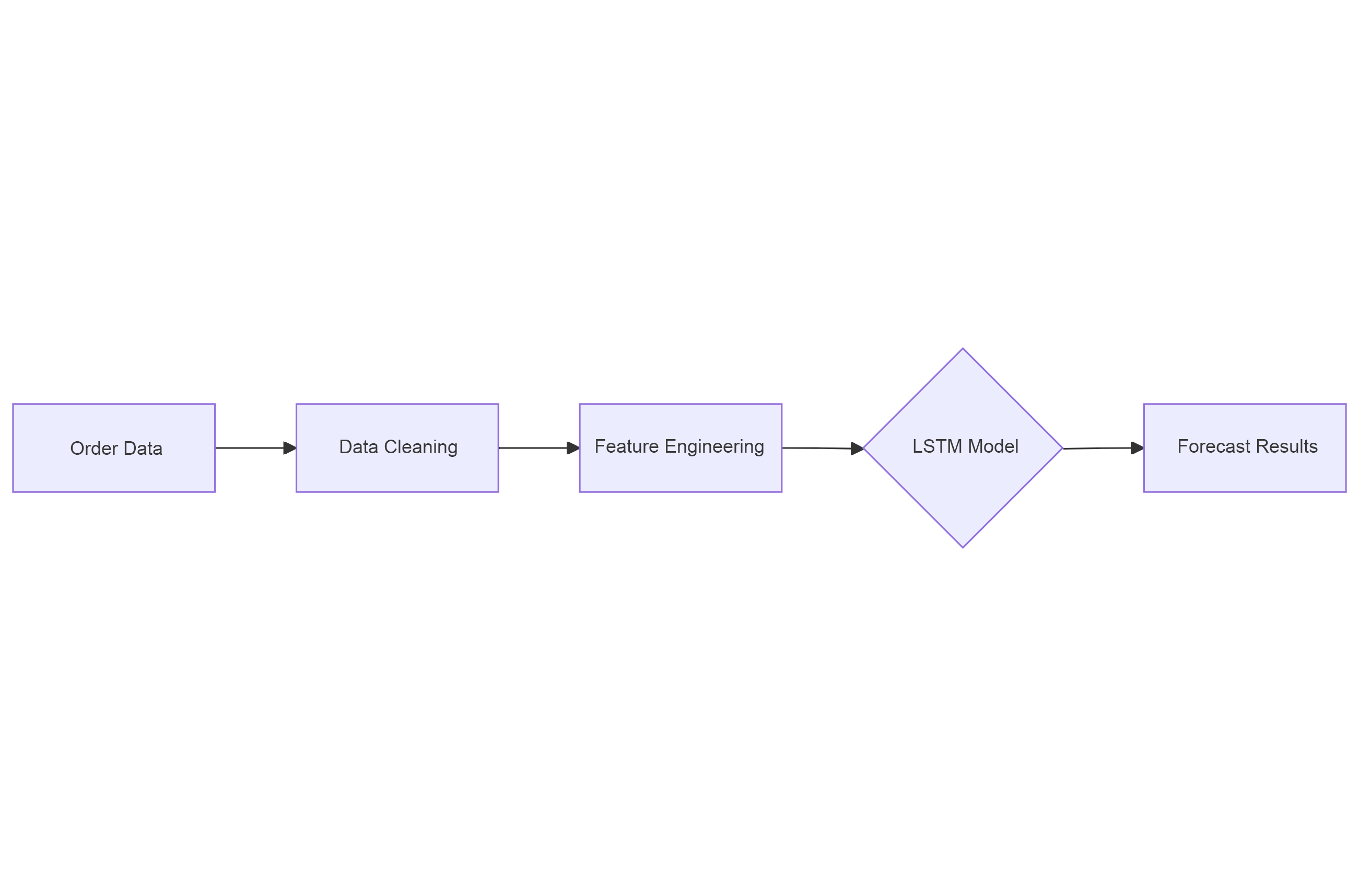

3.3 AI Predictive Systems

3.3.1 Semi-Finished Goods Demand Model

Inputs:

✓ 7-day order forecasts

✓ WIP inventory status

✓ Historical consumption patterns

3.3.2 Defect Prediction

- Model: XGBoost algorithm

- Critical Parameters:

- Finish-rolling temp (Weight: 0.32)

- Rolling force (0.25)

- Cooling rate (0.18)

4. Implementation & Governance

4.1 Methodology

- Lean "Consulting + Design + Agile Development" model for commercial goals

- Onsite teams conduct Figma prototyping and rapid validation, slashing IT-business alignment time.

- Agile iterations minimize time-to-market (TTM) and capex risks.

- Python-based open frameworks for ecosystem flexibility

- Cloud-native architecture breaks legacy lock-in, enabling Industry 4.0 transition

4.2 Phased Rollout

- Foundation (1–3 months):

- Network upgrades

- Data standardization

- Deployment (4–6 months):

- MES module rollout

- Historical data migration

- AI Enhancement (7–12 months):

- Model training

- Digital twin deployment

4.3 Change Management

- Three-tier training:

✓ Leadership: Digital strategy

✓ Middle mgmt.: System administration

✓ Frontline: Certified operations

5. Expected Benefits

5.1 Direct Economic Gains

| Metric | Before | Target | Annualized Benefit |

|---|---|---|---|

| Order cycle time | 45 days | 32 days | ¥18M |

| Quality loss costs | 3.2% | 2.1% | ¥6.5M |

| Inventory turnover | 6.8/yr | 9.2/yr | ¥12M |

5.2 Operational Improvements

- Standardized process database reduces human errors

- End-to-end visibility boosts decision efficiency by 40%

6. Case Study

Results for a 10M-ton steelmaker:

- Orders: Processing time cut from 4h → 30min; emergency response +50%

- Production: Caster utilization up from 82% → 91%; rolling energy use -7.5%

- Quality: Defect detection 88% → 99.3%; tracing time -95%