Solution Overview

This solution leverages advanced algorithms and data analytics to optimize inventory management. Its core lies in accurately forecasting market demand, managing stock levels efficiently, reducing inventory costs, and improving operational efficiency and customer satisfaction.

What is Inventory Optimization?

Inventory Optimization is the scientific management of stock levels, structure, and turnover using strategic methodologies. It aims to balance supply and demand, reduce costs (storage, stockouts, capital occupancy), and improve operational and customer outcomes. The goal is to strike the right balance between “stock availability” and “cost-efficiency”, avoiding overstock or shortages.

Challenges in Inventory Optimization

- Demand Volatility:Market demand is unpredictable due to consumer preferences, economic changes, and external events—leading to overstocking or missed sales.

- Supply Chain Complexity:With globalization, coordinating across suppliers, manufacturers, and distributors has become increasingly difficult.

- Product Complexity:Managing large numbers of SKUs with different storage, transport, and lifecycle requirements increases complexity.

- Seasonality:Industries like fashion and tourism experience sharp demand shifts, requiring precise pre-season planning.

- Evolving Business Models:Omnichannel retail and e-commerce disrupt traditional inventory distribution, requiring more agile planning.

Benefits of Inventory Optimization

- Reduced Holding Costs:Avoid excess inventory and storage fees using accurate safety stock calculations and forecasting.

- Minimized Stockouts:Meet fluctuating demand reliably to prevent lost sales.

- Improved Efficiency:Faster picking, shorter replenishment cycles, and smoother operations.

- Better Cash Flow & Profitability:Free up working capital and reduce unsold stock losses.

- Higher Customer Satisfaction:Maintain stock availability to enhance service levels and loyalty.

Optimization Methods

The inventory optimization solution relies on accurate demand forecasting—predicting the quantity of products customers will purchase in the future—and effective control of inventory levels.

Demand Forecasting Algorithms

A combined approach using time series analysis and machine learning is employed to improve demand forecasting accuracy.

- Time Series Analysis:Uses historical sales data to build models that capture trends and seasonal patterns in demand.

- Machine Learning Algorithms:Introduces support vector regression (SVR) models, incorporating external factors such as macroeconomic indicators and industry trends to improve forecast accuracy.

Inventory Control Algorithms

- Safety Stock Algorithm: Calculates appropriate safety stock levels by factoring in demand uncertainty and supply stability, ensuring sufficient inventory during demand fluctuations or supply disruptions.

- Material Requirements Planning (MRP): Determines precise raw material and component needs based on order forecasts, enabling accurate inventory control and efficient production planning.

Implementation

Data Collection and Preparation

- Gather historical data, including sales, production, inventory, and procurement records.

- Collect external data such as macroeconomic indicators, industry reports, and market trends.

- Clean and preprocess the data by removing outliers and handling missing values to ensure high data quality.

Model Training and Optimization

- Train and optimize machine learning models using historical data; fine-tune model parameters to improve forecast accuracy.

- Calculate economic order quantity (EOQ) and safety stock levels to build inventory control models.

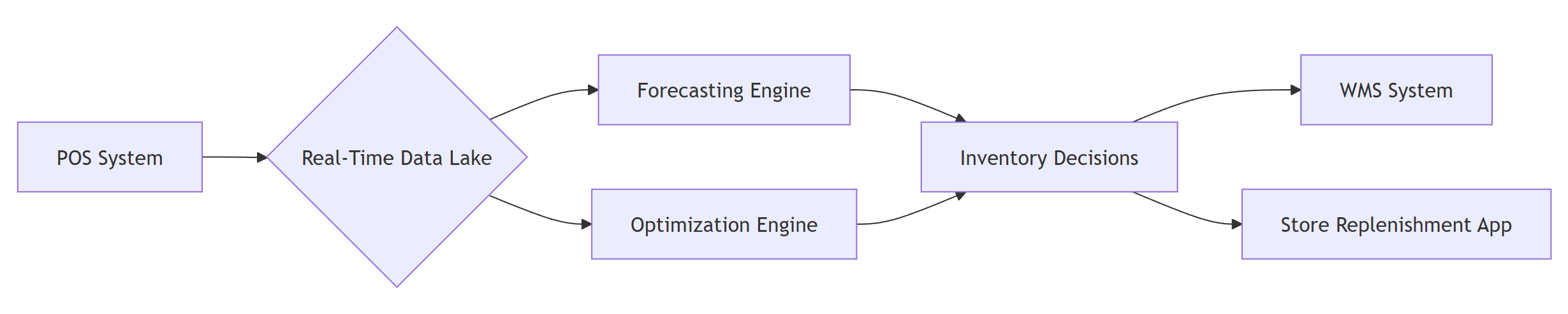

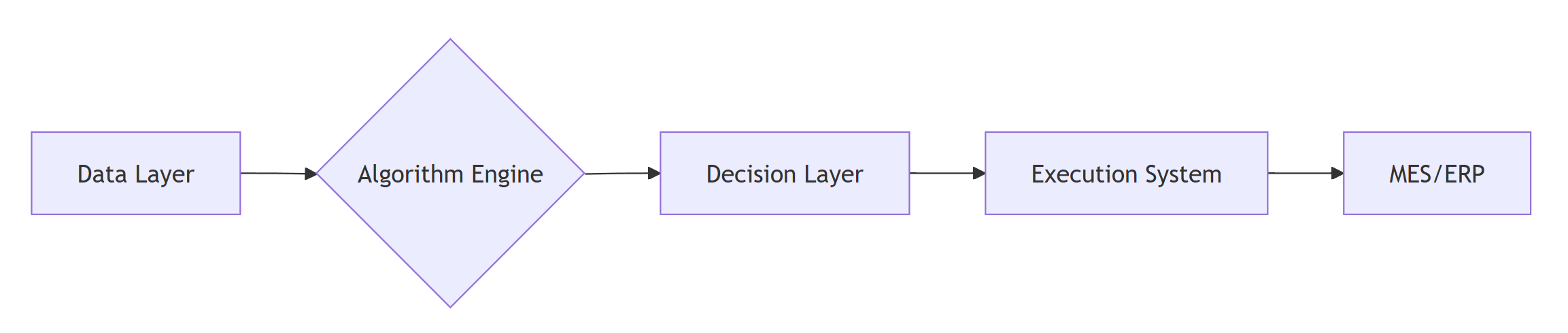

System Integration and Deployment

- Integrate demand forecasting and inventory control models into the inventory management system.

- Enable real-time data updates and automated calculations to maintain inventory accuracy and responsiveness.

- Conduct system testing and validation to ensure stability and reliability.

Monitoring and Adjustment

- Continuously monitor inventory levels, forecast outputs, and actual sales to detect issues and make timely adjustments.

- Regularly update and optimize models in response to market shifts and business strategy changes, ensuring long-term effectiveness and adaptability.

Use Case

Steel Industry

Industry Pain Points

- High volatility in raw material (iron ore/coke) futures prices.

- Long production cycles and severe WIP (work-in-progress) inventory backlog.

- Uncertainty from both market and regulatory factors.

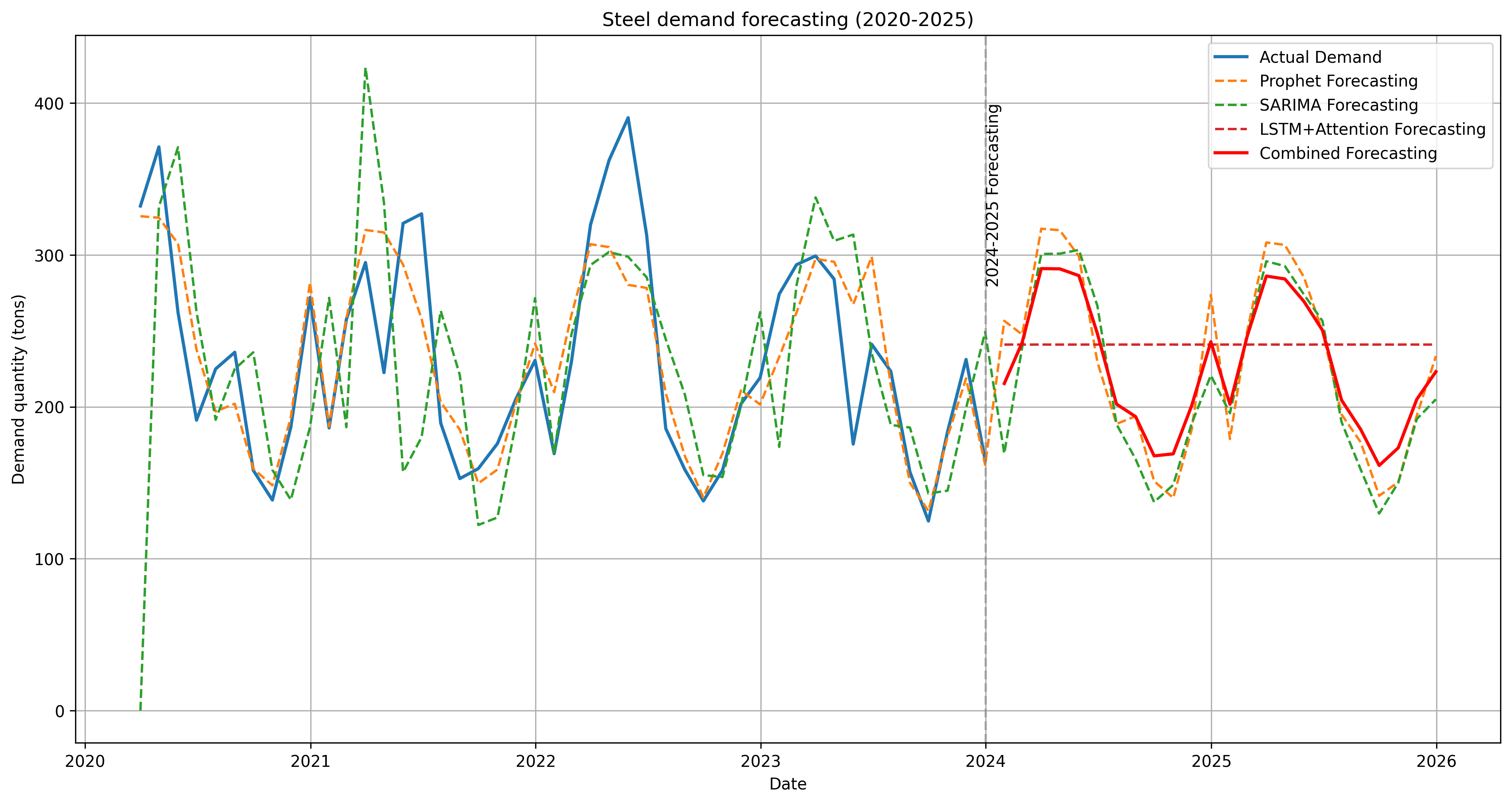

Demand Forecasting: Hybrid Forecasting Model

Objective:Address the steel industry's challenge of “high demand volatility and low forecast accuracy” by achieving precise forecasting at the order and specification levels.

Data Integration and Preprocessing

- Multi-source Data Collection

- Internal Data:

- Production: blast furnace efficiency, rolling mill downtime records, WIP inventory levels, BOM.

- Orders: customer demand specifications (e.g., plate thickness, steel grade), delivery cycle, historical fulfillment rate.

- Supply Chain: iron ore/coke procurement prices, supplier on-time delivery rate, logistics cost.

- External Data:

- Market Trends: raw material pricing, purchasing indexes in downstream sectors (construction, automotive), macroeconomic PMI.

- Environmental Factors: regional production restriction policies, port congestion indexes.

- Feature Engineering

- Construct steel demand features, including time-based variables, industry indicators (e.g., infrastructure investment, rebar pricing), and order characteristics.

Hybrid Forecasting Model Architecture

- Model Architecture

| Model Type | Application | Recommended Algorithm |

|---|---|---|

| Base Forecasting | General order trend prediction | Prophet/SARIMA |

| Surge Demand Prediction | Urgent order identification | LSTM+Attention |

| Policy Impact Forecast | Policy-driven demand shifts | Bayesian Structural Time Series |

- Model Combinations

- Combine multiple models (time series + machine learning) to improve prediction accuracy through ensemble modeling.

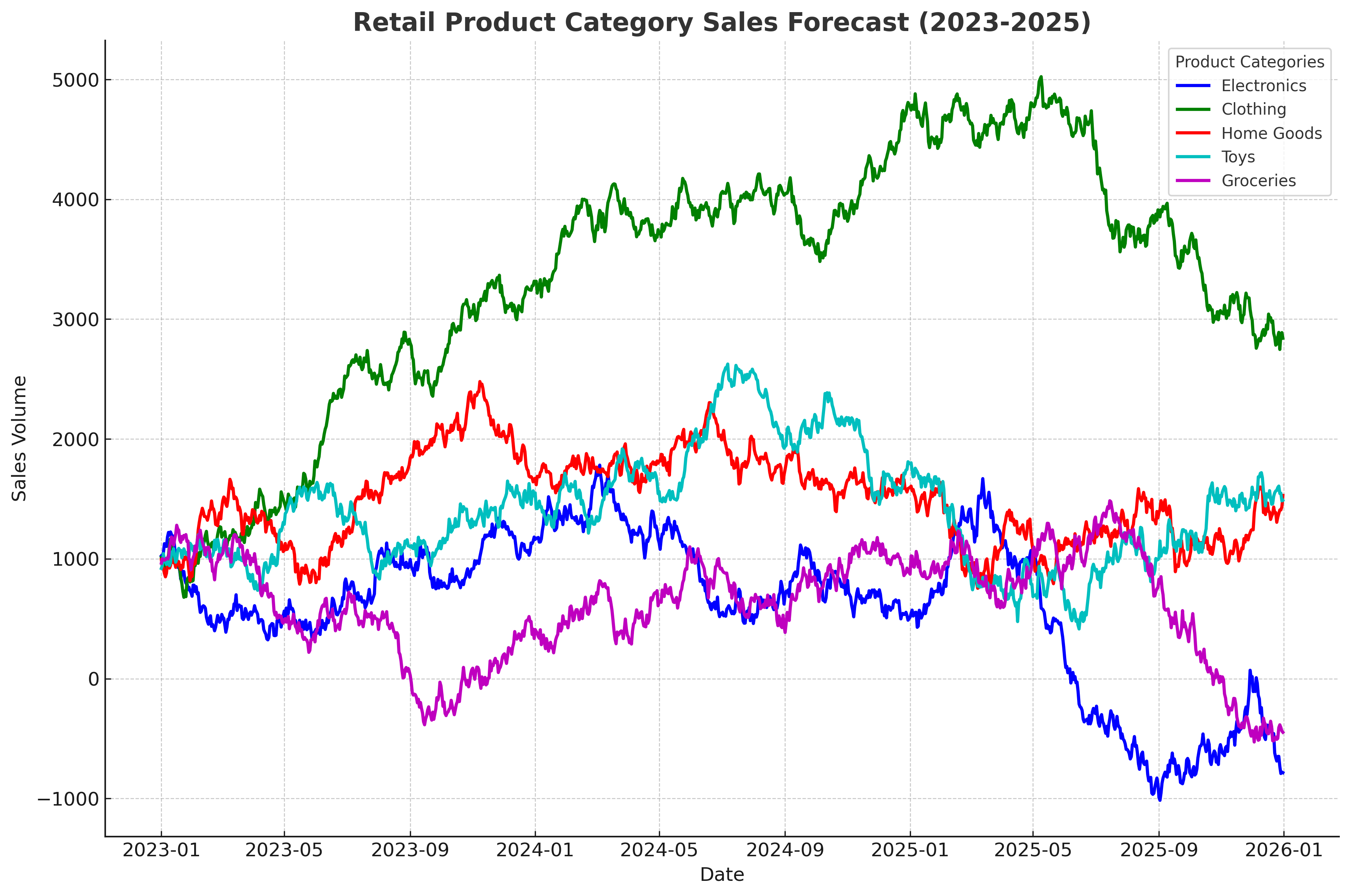

- Sales Forecasting Example

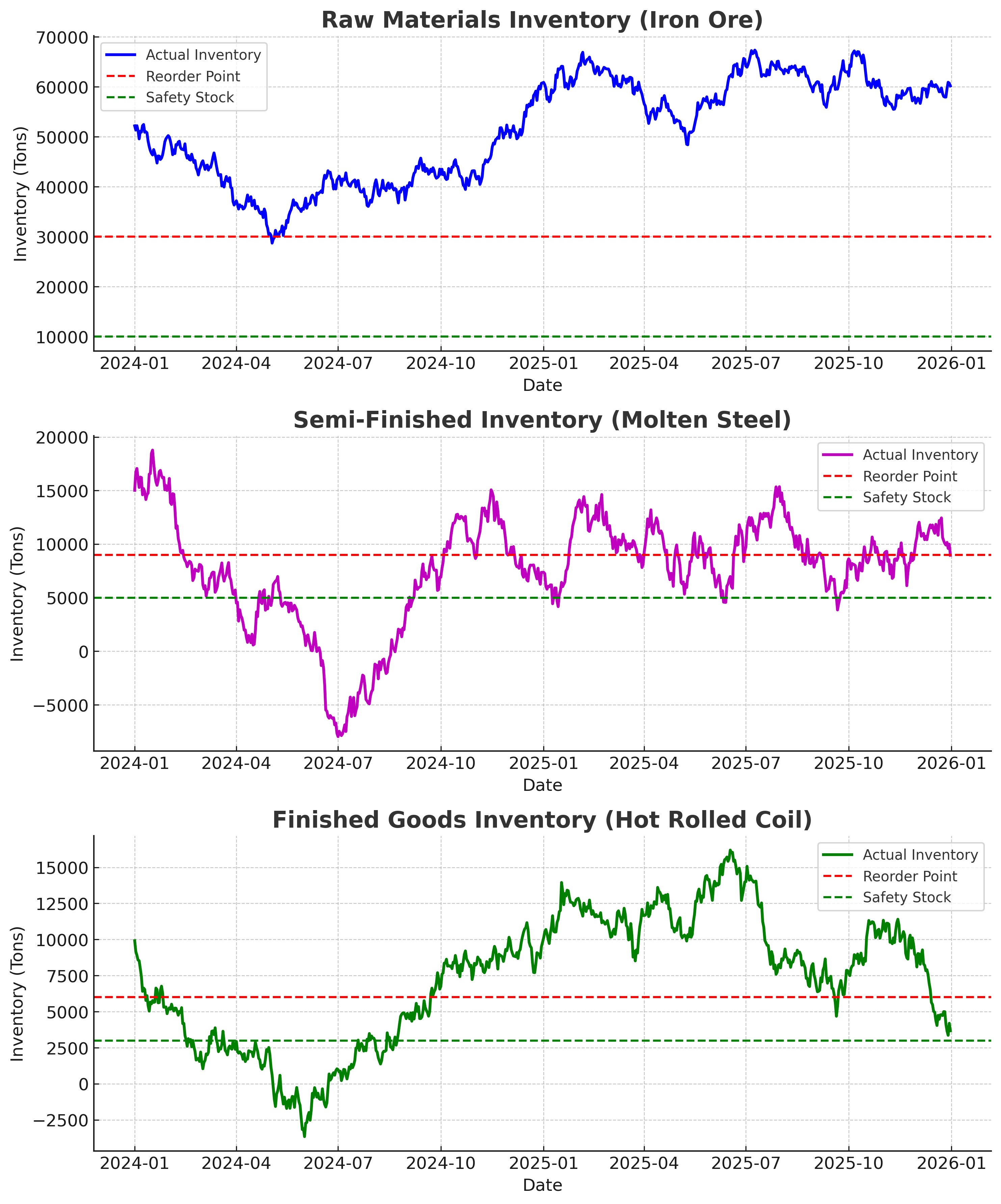

Inventory Control: Multi-Level Optimization + Production Scheduling Synergy

Objective:Optimize inventory across raw materials, WIP, and finished goods to balance service levels and holding costs.

Multi-Level Inventory Modeling

- Inventory Tier Classification

| Inventory Tier | Optimization Focus | Mathematical Model |

|---|---|---|

| Raw Materials | Hedging against commodity price swings | (s, S) policy + futures hedging model |

| Work-In-Progress | Buffer inventory between production steps | Queuing network model |

| Finished Goods | Coordinated regional warehouse dispatch | Multi-echelon inventory location-routing model |

- Dynamic Safety Stock Calculation

Real-Time Optimization Engine

- Algorithm Selection

| Problem Type | Algorithm | Advantage |

|---|---|---|

| Raw Material Procurement | Stochastic Dynamic Programming | Handles price uncertainty |

| Production Scheduling | Enhanced Genetic Algorithm | Manages complex process constraints |

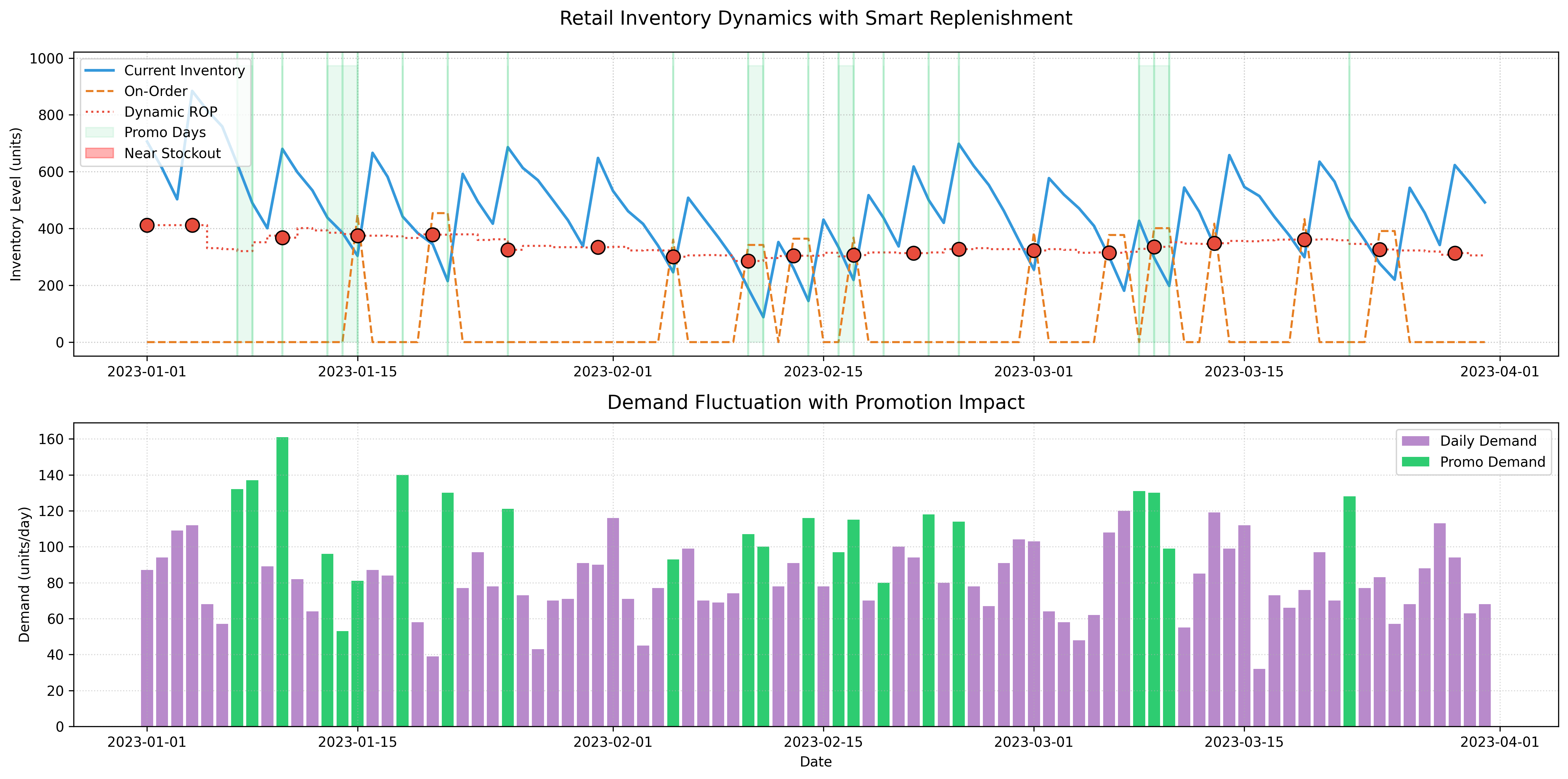

Inventory Fluctuation Example

Technical Architecture

Retail Industry

Industry Pain Points

- A large number of SKUs with demand significantly affected by seasonality and promotions

- Uneven inventory distribution across stores, with simultaneous stockouts of popular items and overstock of slow-moving goods

- High transfer costs and slow response times

Demand Forecasting: Multi-Dimensional Fusion Model

Objective:Accurately forecast demand at the individual store and SKU level to handle seasonal fluctuations, promotional events, and changing consumer behavior—enabling demand-driven replenishment.

- Data Integration

- Internal Data

- Historical sales data: SKU-level and store-level sales, by day/week granularity, including return records

- External influence factors: promotion calendars, holiday flags, weather data, competitor pricing

- Inventory dynamics: real-time stock levels, in-transit inventory, supplier lead times

- Loyalty/member data: purchase frequency, basket size, preference tags

- External Data

- Holiday calendars and major e-commerce event schedules

- Feature Engineering

- Construction of retail demand features: time-based, product-based, and environmental features

- Internal Data

- Layered Forecasting Models

- Model Architecture

- Promotion Impact Modeling

- Baseline sales forecasting, promotional uplift estimation

| Level | Forecast Target | Algorithm | Features |

|---|---|---|---|

| Strategic | Annual category-level demand | Prophet + Bayesian Structural Models | Captures long-term trends and product life cycles |

| Tactical | Weekly demand per SKU | LightGBM + Temporal Attention Mechanism | Accounts for overlapping promotions |

| Operational | Real-time store-level restocking | LSTM + Reinforcement Learning | Responds to sudden spikes in foot traffic |

Dynamic Forecast Calibration

Sales Forecasting Example

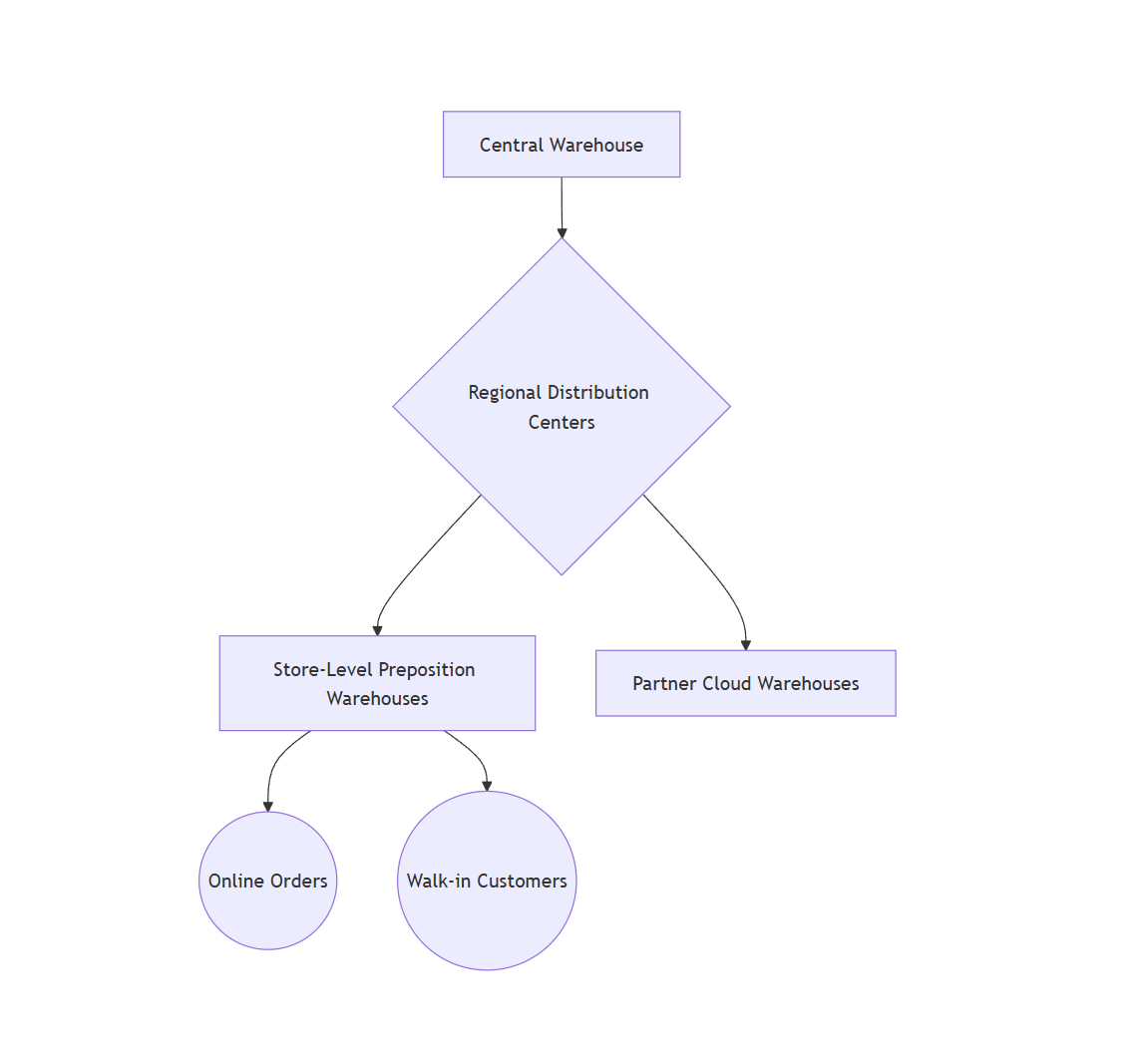

Inventory Control: Multi-Level Inventory Optimization

Objective:Enable personalized, store-specific inventory configurations (“1,000 stores, 1,000 profiles”), balancing the risk of overstock and stockouts, and optimizing the omnichannel inventory network.

- Multi-Level Inventory Optimization Model

- Smart Replenishment Engine

| Product Category | Replenishment Strategy | Mathematical Model |

|---|---|---|

| Bestsellers | Dynamic Safety Stock(s, S) | Markov Decision Process |

| Long-Tail Products | Joint Replenishment Model | Integer Programming + Clustering Analysis |

| Seasonal Products | Extended Newsvendor Model | Optimized Asymmetric Loss Function |

Slow-Moving Inventory Handling Strategies:Markdown pricing strategy, Redistribution across stores (transfer decisions)

Inventory Fluctuation Example

Technical Architecture